Overview

WINLAD Electrical Controls LLC has over twenty-five years of experience in specification, design, development, deployment, project management, and long-term support of large-scale PLC and SCADA system projects. Among the projects we have taken on include but are not limited to the following:

Some of our recent or current projects:

Los Angeles Department of Water and Power:

Water Rehabilitation SCADA System Upgrade:

- Installed and configured the servers and required applications for the scoped task

- Modified existing VBA scripts to conform to the newly upgraded SCADA version.

- Added new VBA scripts to accommodate the scoped functions

- Migrated from legacy communication drivers to ones scoped for and compatible to the upgraded SCADA version.

- Documented Installation & Configuration, and Operator manuals for the upgraded SCADA system.

- Tested, commissioned and performed Operator training of the upgraded SCADA system.

- On-call technical support as needed

Owens Lake Dust Mitigation Phase 910:

Phase 910 scope of work was to develop SCADA and PLC programs for the dust mitigation irrigation process. The platforms included ControlLogix PLCs and iFIX.

- Program Proficy iFIX for data acquisition and process control

- Configure IGS driver for connectivity to field devices

- PLC programming to interface with field instrumentation via TCP/IP

- Perform Factory & Site Acceptance Test

- Perform Loop Checks

Long Beach City Water District:

Phase 1 Water Treatment Plant Upgrade:

Scope of work was to migrate both the SCADA and PLC Platforms. The legacy platforms included SYMAX PLCs and standalone InTouch which were to be migrated to Modicon M340 & M580 PLCs and Wonderware System Platform.

- Installed and configured the SCADA development software within a clustered VM environment.

- Wonderware System Platform programming for data acquisition and process control

- Utilized the KepServer driver for connectivity

- Modicon PLC programming to interface with field instrumentation via TCP/IP and MODBUS

- Performed factory & site acceptance tests

- Performed loop checks

- Startup support and commissioning

- Documentation and operator training

- Provided technical support as required

Chevron – San Joaquin Valley:

Upstream Oil & Gas, Steam Supply Process:

This automated the Steam Splitigator process for two-phase (liquid and vapor) flow distribution. The process design controls steam quality that is delivered to injection wellheads.

- Programed Modicon Quantum PLC code using Unity Pro software for process control.

- Developed Panelview interface using FactoryTalk View ME for local control.

- Developed HMI interface using Wonderware System Platform for visualization and remote control.

- Performed Factory & Site Acceptance Test

- Performed Loop Checks, Startup support and Commissioning

- Documentation and operator training

- Provided technical support as required

Upstream Oil & Gas, Water Plant Pump Staging:

This automated the sequence of a combination of High- and Low-Pressure pumps with different horse powers for efficiency while maintaining their pump curves.

- Program Modicon Quantum PLC code using Unity Pro software for process control.

- Develop Panelview interface using FactorTalk View ME for local control.

- Develop HMI interface using Wonderware System Platform for visualization and remote control.

- Perform Factory & Site Acceptance Test

- Perform Loop Checks

- Startup support and Commissioning

- Documentation and operator training

- Provide technical support as required

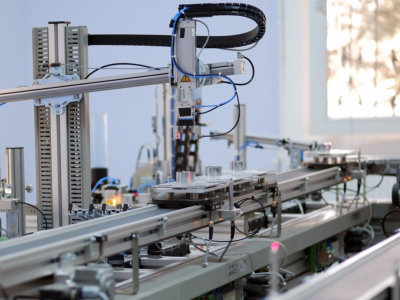

Kavlico Corporation:

Automotive Sensors Production Line:

PLC & microprocessor programming and peripheral interfacing. Configure and propose complete control/acquisition systems for manufacturing process and automation applications. Use of actuators, smart motors, pick and place robotics devices, feedback sensors, fluid dispensers, pneumatics, power tools, microcontrollers, etc.

Take Part in the Solutions that Grow with You

Enlist the expertise of our multi-faceted team to handle your projects. Please get in touch with us by sending us your inquiries here. You may also schedule an appointment with one of our representatives to ensure that we can discuss your needs thoroughly.